Shear the Competition with Our Quality Hydraulic Shearing Machine

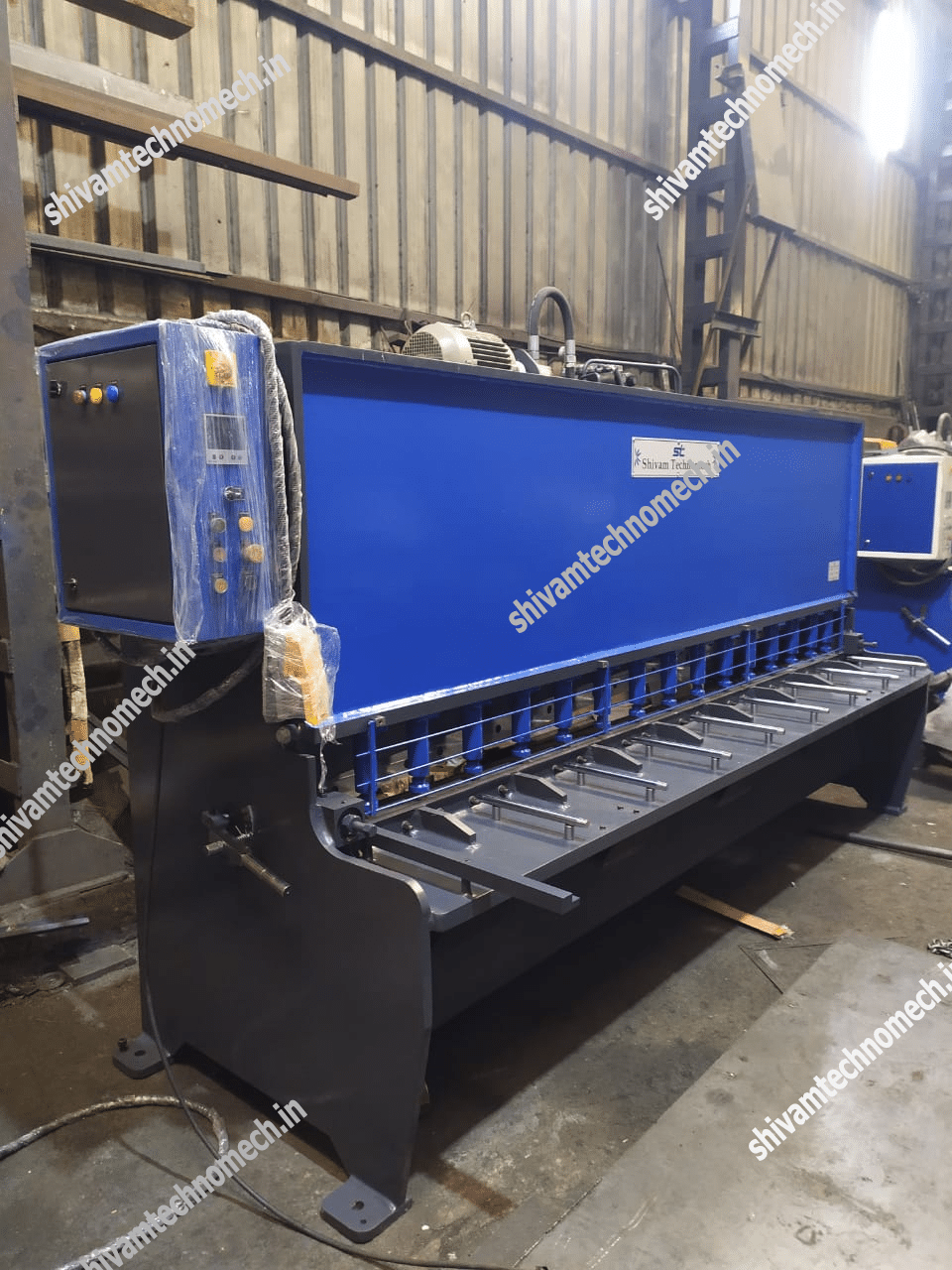

The hydraulic shearing machine manufacturer Shivam Technomech boasts a strong reputation because it produces the most modern equipment with advanced features from modern technology. The hydraulic machines perform essential functions when sheet shearing demands precision because they specialize in sheet metal processing. Our hydraulic shearing machines utilize electronic panels that offer easy-to-use functionality through clear marking of all operations on their interface. The wide range of hydraulic shearing machines exists to accommodate different practical requirements from our potential clients who need sheet metal cutting of varying dimensions. The sheet cutting length ranges from 100 mm to 8000 mm, allowing manufacturing flexibility for various needs. The machines have capabilities to slice through material types, including polycarbonate sheets together with SS, MS, AL, and Cu.

Our careful attention to safety aspects, power usage, and environmentally friendly considerations demonstrates our devotion to high-quality shearing products. Shivam Technomech guarantees the environmental consciousness and efficiency of every hydraulic shearing machine. Our Hydraulic Shearing Machines have a sturdy frame made of premium IS2062 grade heavy-duty material that has undergone UT testing to ensure longevity and dependability in a variety of industrial applications. For hydraulic shearing machines that not only meet but also surpass industry requirements and offer the best performance and accuracy with every cut, choose Shivam Technomech.

Automatic & Semi Automatic hydraulic shearing machine

| Categories | Hydraulic Shearing Machine |

| Brand | Shivam Technomech |

| Model | STHVR |

| Condition | Brand New |

| Structure | IS 2062 Mild Steel |

| Application | Metal Sheet Cutting |

| Metal Processed | Carbon Steel, Stainless Steel, Copper, Aluminium, Galvanized etc.. |

| Automation | Semi Automatic |

| Product Type | Hydraulic |

| Operation | Foot Switch |

| FOB Port | ICD Khodiyar (Gujarat), Mundra Port(Gujarat), Nahva Sheva Port (Maharashtra) |

Standard Features of Hydraulic Shearing Machine

- Digital Stroke Counter with auto rake angle setting

- Stroke Setting Facility with automatic return

- Movable Work Station

- Blade clearance arm for achieve high shearing accuracy.

- Variable rack angle system in upper moving beam for load reducing purpose .

- Manual and Automatic variable rack angle operating system

- Rake angle range 0.5-3 degree

- Heavy duty front mounted hydraulic cylinders for sheet holding

- Four Edge Fine Finished Shearing Blade. MOC:D3/D2/Higher grade

- Solenoid Valve for direction control

- Operated by Electrical Panel

- High efficient Hydraulic Pumps

- Shivam Technomech design Hydraulic cylinder

- Latest design compact Power pack system

- Compact power pack system with upgraded design and technology

- Main drive Electric motor operated

- Foot switch Operated

- Movable work station

-

Types of Back gauge operating system

- Manual Back Gauge operating system

- Motorize Back Gauge operating system

- NC Back Gauge operating system

- Sheet support for sheet holding

- Pressure gauge for display operating pressure

- Easy to control cutting length

- Maximum workflow efficiency and operating convenience

- Ensure high strength and high rigidity during operation

- The frame is interlocked design provides support to the bed directly on the frame to avoid weak sections at load supports.

Technical Specification of Hydraulic Shearing Machine

| Shearing Thickness | |||||||||||

| Model | Shearing Length | M.S. | S.S. | Rake Angle Range | Strokes/Minute Atmin. & Max. rake angle | Hold downs | Power Hp. | Packing Dimensions (LxWxH)MM | |||

| Nominal Rake Angle | Max. Rake Angle | Nominal Rake Angle | Max. Rake Angle | ||||||||

| STHVR2502 | 2500 | 2 | 3.15 | 1 | 1.6 | 0.5-2° | 22-10 | 13 | 3 | 2950x1650x1550 | |

| STHVR3002 | 3000 | 2 | 3.15 | 1 | 1.6 | 0.5-2° | 18-8 | 15 | 3 | 3450x1650x1550 | |

| STHVR1503 | 1500 | 3.15 | 4 | 2 | 3 | 0.5-2° | 24-10 | 8 | 5 | 2300x1900x2100 | |

| STHVR2503 | 2500 | 3.15 | 4 | 2 | 3 | 0.5-2° | 28-13 | 13 | 5 | 3250x1900x2000 | |

| STHVR3003 | 3000 | 3.15 | 4 | 2 | 3 | 0.5-2° | 24-9 | 15 | 5 | 3750x1900x2000 | |

| STHVR1504 | 1500 | 4 | 6 | 3 | 4 | 0.5-3° | 24-10 | 8 | 5 | 2300x1900x2100 | |

| STHVR2004 | 2000 | 4 | 6 | 3 | 4 | 0.5-3° | 22-8 | 11 | 7.5 | 2850x1950x2100 | |

| STHVR2504 | 2500 | 4 | 6 | 3 | 4 | 0.5-3° | 22-8 | 13 | 7.5 | 3400x2350x2500 | |

| STHVR3004 | 3000 | 4 | 6 | 3 | 4 | 0.5-3° | 22-8 | 15 | 10 | 3800x2350x2500 | |

| STHVR4004 | 4000 | 4 | 6 | 3 | 4 | 0.5-3° | 18-6 | 20 | 10 | 4600x2350x2500 | |

| STHVR1506 | 1500 | 6 | 8 | 4 | 6 | 0.5-3° | 24-8 | 8 | 10 | 2350x2000x2200 | |

| STHVR2006 | 2000 | 6 | 8 | 4 | 6 | 0.5-3° | 22-7 | 11 | 10 | 2850x2000x2200 | |

| STHVR2506 | 2500 | 6 | 8 | 4 | 6 | 0.5-3° | 28-8 | 13 | 15 | 3400x2350x2600 | |

| STHVR3006 | 3000 | 6 | 8 | 4 | 6 | 0.5-3° | 24-6 | 15 | 15 | 3900x2350x2600 | |

| STHVR4006 | 4000 | 6 | 8 | 4 | 6 | 0.5-3° | 24-6 | 20 | 20 | 4900x2350x2600 | |

| STHVR1508 | 1500 | 8 | 10 | 6 | 8 | 0.5-3° | 22-10 | 8 | 15 | 2350x2150x2300 | |

| STHVR2008 | 2000 | 8 | 10 | 6 | 8 | 0.5-3° | 18-8 | 11 | 15 | 2850x2150x2300 | |

| STHVR2508 | 2500 | 8 | 10 | 6 | 8 | 0.5-3° | 24-8 | 13 | 20 | 3400x2450x2300 | |

| STHVR3008 | 3000 | 8 | 10 | 6 | 8 | 0.5-3° | 20-6 | 15 | 20 | 4000x2550x2800 | |

| STHVR4008 | 4000 | 8 | 10 | 6 | 8 | 0.5-3° | 20-8 | 20 | 30 | 4900x2450x2700 | |

| STHVR15010 | 1500 | 10 | 13 | 8 | 10 | 0.5-3° | 20-8 | 8 | 15 | 2350x2150x2400 | |

| STHVR20010 | 2000 | 10 | 13 | 8 | 10 | 0.5-3° | 18-8 | 11 | 15 | 2850x2150x2400 | |

| STHVR25010 | 2500 | 10 | 13 | 8 | 10 | 0.5-3° | 24-8 | 13 | 20 | 3400x2600x2900 | |

| STHVR30010 | 3000 | 10 | 13 | 8 | 10 | 0.5-3° | 20-6 | 15 | 20 | 3900x2600x2900 | |

| STHVR40010 | 4000 | 10 | 13 | 8 | 10 | 0.5-3° | 18-6 | 20 | 30 | 4900x2600x2900 | |

| STHVR20013 | 2000 | 13 | 16 | 10 | 13 | 0.5-3° | 13-5 | 11 | 20 | 2850x2300x2600 | |

| STHVR25013 | 2500 | 13 | 16 | 10 | 13 | 0.5-3° | 15-10 | 13 | 25 | 3450x2750x2900 | |

| STHVR30013 | 3000 | 13 | 16 | 10 | 13 | 0.5-3° | 12-6 | 16 | 25 | 3900x2700x2900 | |

| STHVR40013 | 4000 | 13 | 16 | 10 | 13 | 0.5-3° | 10-4 | 20 | 30 | 4950x2300x2900 | |

| STHVR20016 | 2000 | 16 | 20 | 13 | 16 | 0.5-3° | 13-7 | 11 | 25 | 2850x2300x2700 | |

| STHVR25016 | 2500 | 16 | 20 | 13 | 16 | 0.5-3° | 15-8 | 13 | 30 | 3600x2700x3000 | |

| STHVR30016 | 3000 | 16 | 20 | 13 | 16 | 0.5-3° | 12-6 | 16 | 30 | 4100x2700x3000 | |

| STHVR40016 | 4000 | 16 | 20 | 13 | 16 | 0.5-3° | 10-4 | 20 | 30 | 5200x2850x3000 | |

| Capacities rated for M.S. of UTS 45 kg/mm² Yield 28 kg/mm²& S.S. of UTS 72 kg/mm² Yield 45kg/mm² | |||||||||||