Shivam Technomech stands at the forefront of manufacturing excellence with its Hydraulic Press Brake Machine, integrating Latest features and advanced technology. This machine is tailored for sheet metal work, finding extensive application in diverse sheet folding operations. Our product line includes multiple models that fulfill distinct requirements for customer job work with final product finishing processes which offers an intuitive operating system.

The product line of Shivam Technomech includes Hydraulic Press Brake machine models that offer bending lengths between 100mm and 8000mm. The technology demonstrates strong adaptability through bending performance of SS, MS, AL, Cu and polycarbonate sheets at the same time. Model selection options cater to the specific needs of sheet material, thickness, and length, complemented by high-quality bending tools tailored to different sheet folding structures.

Our commitment to design excellence and safety considerations is evident in the meticulous engineering process. The focus on creating noiseless, smooth functionality with low power consumption sets our Hydraulic Press Brake Machine apart. Soft and hard sheets alike can be seamlessly bent at various angles, extending the machine’s utility to embossing and multi-punching applications in straight lengths.

Hydraulic press brake machines find their application in a myriad of industries, including pharma, kitchen equipment manufacturing, ducting, elevator production, electric panel manufacturing, structural sheet metal folding, mechanical workshops, ITI, navy machinery, agriculture equipment manufacturing, container production, and more.

Crafted from UT tested high-quality IS2062 grade heavy-duty material, our hydraulic press brake machine assures durability and reliability in every operation. Shivam Technomech continues to set benchmarks in the industry, delivering machines that redefine precision and efficiency.

Hydraulic Press Brake Machine Manufacturer

| Categories | Hydraulic Press Brake Machine |

| Brand | Shivam Technomech |

| Model | STPB |

| Condition | Brand New |

| Structure | IS 2062 Mild Steel |

| Application | Bending |

| Metal Processed | Carbon Steel, Stainless Steel, Copper, Aluminium, Galvanized etc.. |

| Automation | Semi Automatic |

| Product Type | Hydraulic |

| Operation | Foot Switch |

| FOB Port | ICD Khodiyar (Gujarat), Mundra Port(Gujarat), Nahva Sheva Port (Maharashtra) |

Standard Features of Hydraulic Press Brake Machine

- High Capacity Power pack system

- Heavy duty Electric motor for main drive

- Three type mode of operation – Manual ,Semi Auto and Auto

- Foot switch Operated

- Movable work station

-

Different type of Back gauge system

- Manual Back Gauge system

- Motorize Back Gauge system

- NC Back Gauge system

- Oil cup or Hand pump type lubrication system

- Sheet support for sheet holding

- Easy die lifting and tilting facility

- High quality EN31 or imported Die

- High quality EN31 or imported Punch

- Special design Hydraulic cylinder

- Sufficient throat depth

- Fast and slow speed controlling system

- Double hydraulic pump operated hydraulic system

- Electric panel operated

- Direction control solenoid valve

- Pressure gauge for display operating pressure

Technical Specification of Hydraulic Press Brake Machine

| Model | Tonnage | Table Length | Bending Capacity (In MS. UTS 45kg/mm²) in mm | Table Width in mm | Clear pass in mm | Ram Stroke in mm | Open Height in mm | Throat Depth in mm | Speed Approach Passing Return mm/sec | Power HP | Packing Dimensions (L x W x H) in mm | |

| A | B | C | D | E | F | G H I | ||||||

| STPBR1520 | 20 | 1500 | 1.6×1500 | 2×1250 | 150 | 1050 | 100 | 250 | 200 | 25-7-30 | 3 | 1800x1150x2000 |

| STPBR2030 | 30 | 2000 | 2×2000 | 3×1250 | 150 | 1550 | 100 | 250 | 200 | 23-6-30 | 3 | 2300x1250x2000 |

| STPBR2540 | 40 | 2500 | 2×2500 | 3×1500 | 150 | 2050 | 100 | 250 | 200 | 23-6-30 | 5 | 2800x1250x2000 |

| STPBR1550 | 50 | 1500 | 4×1500 | 5×1250 | 190 | 1050 | 100 | 250 | 200 | 23-6-30 | 5 | 1800x1250x2000 |

| STPBR2050 | 50 | 2000 | 3×2000 | 4×1500 | 190 | 1550 | 100 | 250 | 200 | 23-6-30 | 5 | 2300x1250x2000 |

| STPBR2550 | 50 | 2500 | 2.5×2500 | 3×2000 | 190 | 2050 | 100 | 250 | 200 | 23-6-33 | 5 | 2800x1250x2000 |

| STPBR2565 | 65 | 2500 | 3×2500 | 4×2000 | 190 | 2050 | 150 | 330 | 200 | 28-4-30 | 5 | 2800x1300x2100 |

| STPBR3065 | 65 | 3050 | 2.5×3000 | 3×2500 | 190 | 2550 | 150 | 330 | 200 | 28-4-30 | 5 | 3450x1300x2100 |

| STPBR2580 | 80 | 2500 | 4×2500 | 5×2000 | 190 | 2050 | 150 | 330 | 200 | 35-5-43 | 7.5 | 2800x1650x2400 |

| STPBR3080 | 80 | 3050 | 3×3000 | 4×2500 | 190 | 2550 | 150 | 330 | 200 | 35-5-43 | 7.5 | 3450x1650x2400 |

| STPBR25100 | 100 | 2500 | 5×2500 | 6×2000 | 190 | 2050 | 150 | 330 | 200 | 35-5-43 | 7.5 | 2800x1650x2400 |

| STPBR30100 | 100 | 3050 | 4×3000 | 5×2500 | 190 | 2550 | 150 | 330 | 200 | 35-5-43 | 7.5 | 3450x1650x2400 |

| STPBR40100 | 100 | 4050 | 3×4000 | 4×3000 | 250 | 3250 | 150 | 330 | 200 | 35-5-43 | 7.5 | 4350x1750x2400 |

| STPBR25125 | 125 | 2500 | 6×2500 | 8×2000 | 250 | 2150 | 150 | 350 | 300 | 35-4-38 | 10 | 2850x1750x2600 |

| STPBR30125 | 125 | 3050 | 5×3000 | 6×2500 | 250 | 2650 | 150 | 350 | 300 | 35-4-38 | 10 | 3450x1750x2600 |

| STPBR40125 | 125 | 4050 | 4×4000 | 5×3000 | 250 | 3250 | 150 | 350 | 300 | 35-4-38 | 10 | 4300x1750x2600 |

| STPBR25160 | 160 | 2500 | 8×2500 | 10×2000 | 300 | 2150 | 150 | 350 | 300 | 32-4-38 | 15 | 2850X1900x2700 |

| STPBR30160 | 160 | 3050 | 6×3000 | 8×2500 | 300 | 2650 | 150 | 350 | 300 | 32-4-39 | 15 | 3450x1900x2700 |

| STPBR40160 | 160 | 4050 | 5×4000 | 6×3000 | 300 | 3250 | 150 | 350 | 300 | 32-5-39 | 15 | 4450x1900x2700 |

| STPBR25200 | 200 | 2500 | 10×2500 | 12×2000 | 300 | 2150 | 200 | 400 | 300 | 32-6-33 | 20 | 2950X2150x2850 |

| STPBR30200 | 200 | 3050 | 8×3000 | 10×2500 | 300 | 2650 | 200 | 400 | 300 | 32-6-33 | 20 | 3450x2150x2850 |

| STPBR40200 | 200 | 4050 | 6×4000 | 8×3000 | 300 | 3250 | 200 | 400 | 300 | 32-6-33 | 20 | 4450x2150x2850 |

| STPBR30250 | 250 | 3050 | 10×3000 | 12×2500 | 350 | 2650 | 200 | 400 | 300 | 32-5-39 | 25 | 3450X2200x2900 |

| STPBR40250 | 250 | 4050 | 8×4000 | 10×3000 | 350 | 3250 | 200 | 400 | 300 | 32-5-39 | 25 | 4450x2200x2900 |

| STPBR30300 | 300 | 3050 | 12×3000 | 15×2500 | 350 | 2650 | 200 | 400 | 300 | 28-5-33 | 30 | 3450x2250x3000 |

| STPBR40300 | 300 | 4050 | 10×4000 | 12×3000 | 350 | 3250 | 200 | 400 | 300 | 28-4-31 | 30 | 4450x2250x3000 |

| STPBR30400 | 400 | 3050 | 16×3000 | 20×2500 | 350 | 2650 | 250 | 500 | 350 | 28-4-31 | 40 | 3450x2300x3100 |

| STPBR40400 | 400 | 4050 | 12×4000 | 16×3000 | 350 | 3250 | 250 | 500 | 350 | 28-4-31 | 40 | 4450x2300x3100 |

Color: Blue And White

Usage: Industrial

Product Type:Hydraulic Nc Press Brake Machine

Size:Standard

Supply Ability:10 Per Month

Delivery Time:7-10 Days

Color: Blue And White

Usage: Industrial

Product Type: NC Hydraulic Press Brakes Machine

Size:Standard

Supply Ability:10 Per Month

Delivery Time:7-10 Days

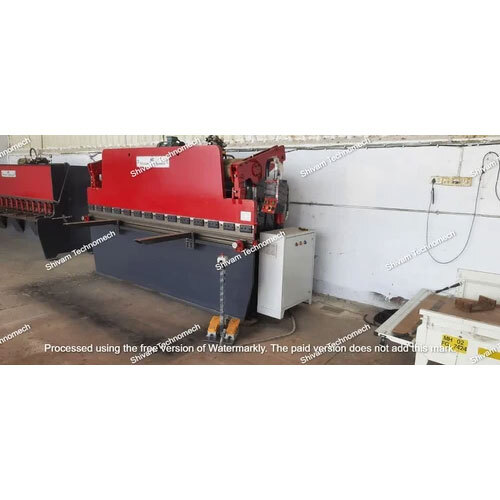

Color: Red

Usage: Industrial

Product Type:Hydraulic Press Brake Machine

Size:Standard

Supply Ability:10 Per Month

Delivery Time:7-10 Days

Color: Red

Usage: Bending

Product Type: Automatic Nc Press Brake Machine

Size: Standard

Supply Ability: 10 Per Month

Delivery Time: 7-10 Days

Color: Green And White

Usage: Sheet Bending

Product Type: Nc Control Hydraulic Press Brake

Size: Standard

Supply Ability: 10 Per Month

Delivery Time: 7-10 Days

Color: Red And White

Usage: Sheet Bending

Product Type: Press Brakes

Size: Standard

Supply Ability: 10 Per Month

Delivery Time: 7-10 Days