Exploring the Role of Hydraulic Press Machine Manufacturers in Modern Industry

Hydraulic press machines have become indispensable in today’s manufacturing landscape, offering unmatched power, precision, and versatility across a wide array of applications. As industries continue to evolve and demand more efficient production methods, the role of hydraulic press machine manufacturers becomes increasingly significant. These manufacturers are at the forefront of innovation, ensuring that businesses have access to advanced machinery capable of meeting stringent production standards and enhancing overall productivity.

Understanding Hydraulic Press Machines

A hydraulic press machine is a device that uses a hydraulic cylinder to generate a compressive force. It operates on the principle of Pascal’s law, which states that pressure applied to a confined fluid is transmitted equally in all directions. This technology allows hydraulic press machines to exert immense force, making them ideal for tasks such as forming, molding, punching, forging, and metal shaping. The versatility and efficiency of hydraulic presses make them a preferred choice in various industries, from automotive and aerospace to electronics and heavy machinery.

Key Features of Hydraulic Press Machines

Hydraulic press machines are renowned for their robust construction and exceptional performance capabilities. Some of the key features that make these machines stand out include:

High Precision and Control: Hydraulic press machines offer precise control over the force and speed of the pressing action. This accuracy is crucial in applications requiring consistent and high-quality outputs, such as metal forming and molding processes.

Flexibility: These machines can be easily adjusted to accommodate different materials, shapes, and sizes. This flexibility allows manufacturers to use a single machine for various tasks, enhancing operational efficiency.

Power and Efficiency: Hydraulic press machines can generate significant force, making them capable of handling tough materials and complex tasks with ease. Despite their power, these machines are designed to be energy-efficient, reducing operational costs for manufacturers.

Safety Features: Modern hydraulic press machines are equipped with advanced safety features, including emergency stop buttons, pressure relief valves, and automated monitoring systems. These features ensure safe operation and protect operators from potential hazards.

Durability and Reliability: Built with high-quality materials and components, hydraulic press machines are designed for long-term use. Their durability and reliability make them a valuable investment for manufacturers seeking consistent performance over time.

The Role of Hydraulic Press Machine Manufacturers

Hydraulic press machine manufacturers play a crucial role in the industrial ecosystem. Their responsibilities extend beyond merely producing machinery; they are involved in research and development, customization, and after-sales support, ensuring that clients receive comprehensive solutions tailored to their specific needs. Here are some of the key contributions of hydraulic press machine manufacturers:

Innovation and Development: Manufacturers invest heavily in research and development to create advanced hydraulic press machines that incorporate the latest technologies. Innovations such as computer numerical control (CNC) systems, automated handling, and real-time monitoring have significantly enhanced the capabilities of these machines.

Customization: Every industry has unique requirements, and hydraulic press machine manufacturers offer customized solutions to meet these specific needs. Whether it’s designing a machine with a particular capacity, integrating specialized tooling, or developing bespoke control systems, manufacturers work closely with clients to deliver tailored machinery.

Quality Assurance: Ensuring the highest standards of quality is paramount for hydraulic press machine manufacturers. Rigorous testing and quality control measures are implemented at every stage of production to guarantee that each machine meets industry standards and performs reliably in demanding environments.

Technical Support and Training: Manufacturers provide comprehensive technical support and training to help clients maximize the potential of their hydraulic press machines. This includes installation, maintenance, troubleshooting, and operator training, ensuring that clients can operate the machinery safely and efficiently.

Applications of Hydraulic Press Machines

The applications of hydraulic press machines are vast and varied, spanning numerous industries and sectors. Some of the most common applications include:

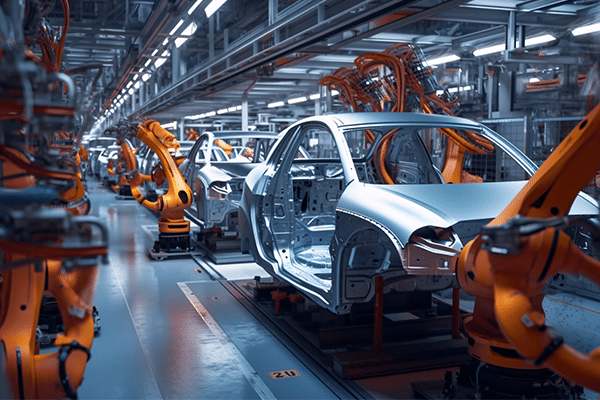

Automotive Industry

Hydraulic press machines are used extensively in the automotive sector for tasks such as forming body panels, assembling components, and forging parts. The precision and power of these machines ensure high-quality outputs and efficient production processes.

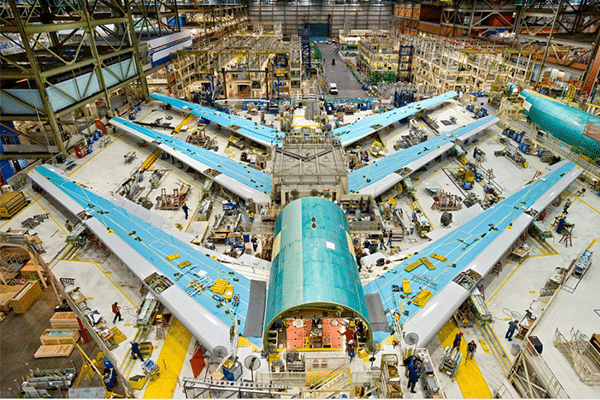

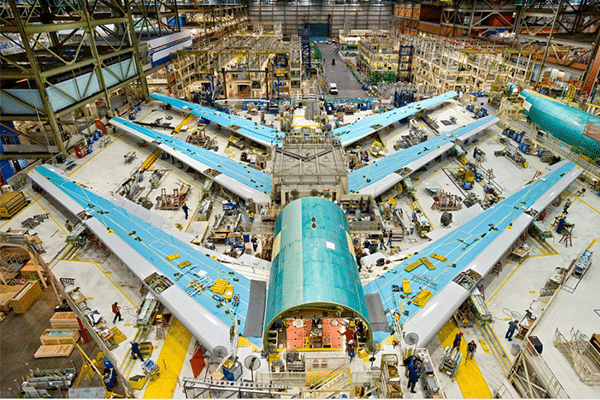

Aerospace Industry

In the aerospace sector, hydraulic presses are employed in the manufacturing of aircraft components, including wings, fuselage parts, and engine components. The ability to handle high-strength materials and complex shapes makes hydraulic presses indispensable in this industry.

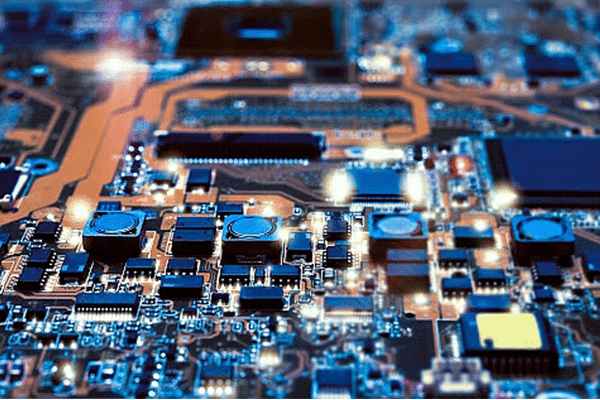

Electronics Industry

Hydraulic press machines are used in the production of electronic components, including circuit boards, connectors, and casings. The precision and control offered by these machines are crucial for ensuring the integrity and performance of electronic products.

Construction Industry

Hydraulic presses are utilized in the construction sector for tasks such as shaping and forming building materials, including metal beams, columns, and panels. The robustness and reliability of these machines make them ideal for heavy-duty applications.

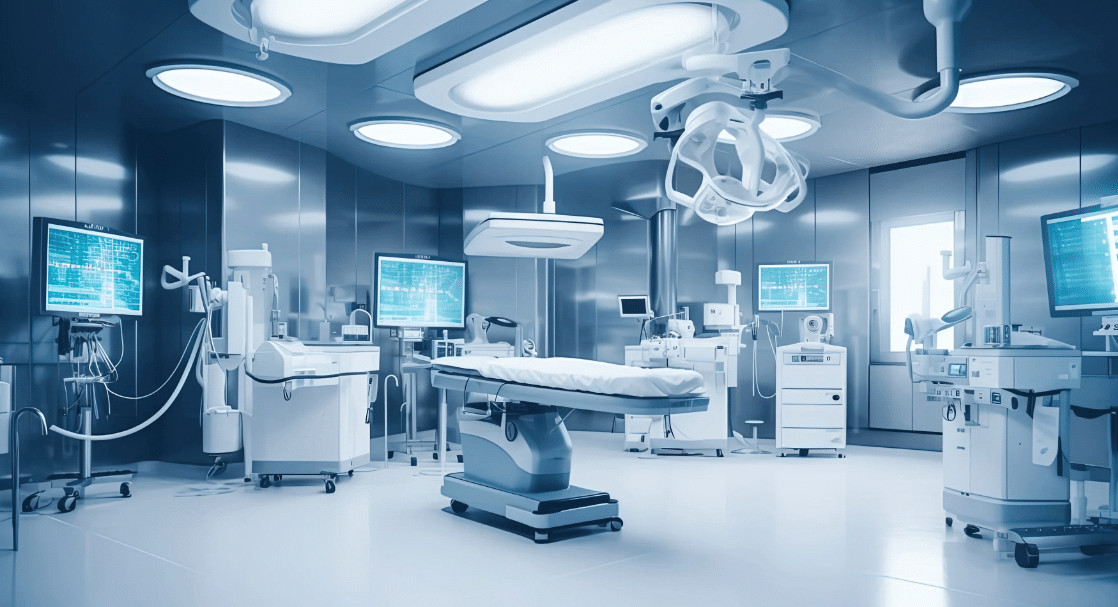

Medical Industry

In the medical field, hydraulic press machines are used to manufacture medical devices, implants, and surgical instruments. The high precision and cleanliness standards required in this industry make hydraulic presses a preferred choice.

Future Trends in Hydraulic Press Machine Manufacturing

The future of hydraulic press machine manufacturing is marked by continued innovation and technological advancements. Key trends shaping the industry include:

Automation and Integration: The integration of automation technologies, such as robotics and artificial intelligence, is revolutionizing hydraulic press machine operations. Automated systems enhance efficiency, reduce human error, and allow for seamless integration with other manufacturing processes.

Smart Manufacturing: The adoption of Industry 4.0 principles, including the Internet of Things (IoT) and data analytics, is transforming hydraulic press machines into smart, connected devices. Real-time monitoring, predictive maintenance, and data-driven decision-making are becoming integral to modern manufacturing.

Sustainable Manufacturing: As sustainability becomes a priority, hydraulic press machine manufacturers are focusing on developing eco-friendly solutions. This includes energy-efficient designs, the use of recyclable materials, and the implementation of green manufacturing practices.

Advanced Materials: The development of new materials, such as high-strength alloys and composites, is driving the need for advanced hydraulic press machines capable of handling these materials. Manufacturers are continually innovating to meet the demands of evolving material technologies.