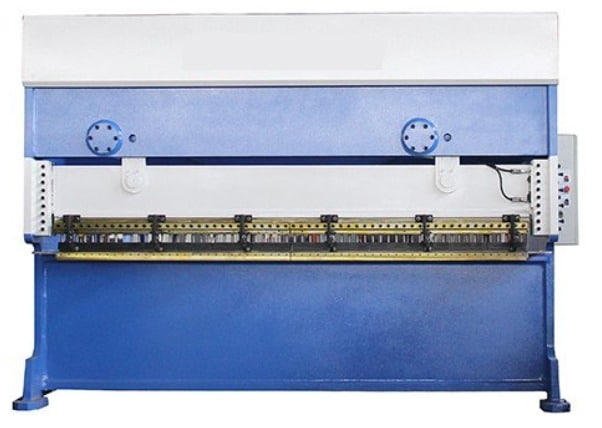

Shivam Technomech is manufacturing Hydraulic Aluminium Formwork Holes Punching Machine with the latest features and advance technology. It is mainly used for Aluminium sheet metal work. Most of these machines are used in Aluminium formwork hole punching. We are supplying types of models according to customer job work and the final finished product. Our Hydraulic Aluminium Formwork Holes Punching Machine operating system is efficient. Shivam Technomech is designing different capacity Hydraulic Aluminium Formwork Holes Punching Machine models.

Our engineering team takes care of machine designing for its noise-less, smooth function with low power consumption. Shivam Technomech is designing different capacity Hydraulic Aluminium Formwork Holes Punching Machine models. Different types of model selection options are available according to material thickness and length. All punching tools are made of high quality materials. Our engineering team takes care of machine design for its noise-less, smooth function with low power consumption.

Hydraulic Aluminium Formwork Holes Punching Machine Manufacturer

Purpose

1. Hydraulic Aluminium Formwork Holes Punching Machine mainly use for the aluminium formwork 80-600mm U Panel and 100×100~200 G profile holes punching.

2. Hydraulic Aluminium Formwork Holes Punching Machine use in different type industries, like Construction work.

Standard Features of Hydraulic Aluminium Formwork Holes Punching Machine

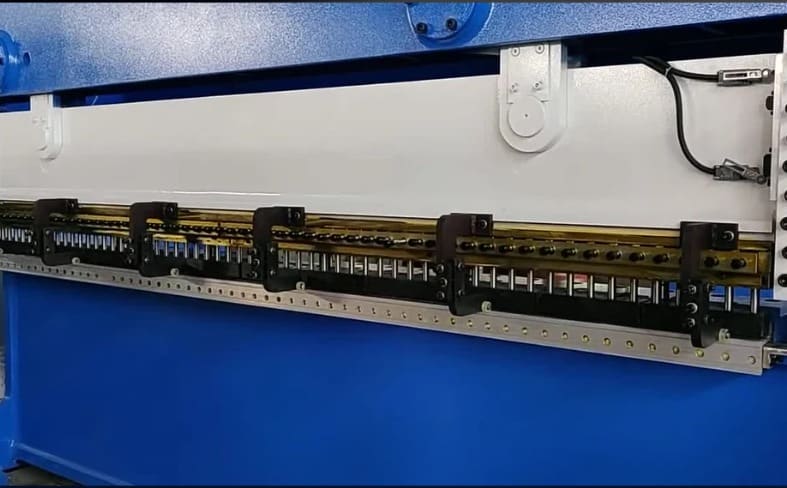

- Hydraulic Aluminium Formwork Holes Punching Machine Structure is made from UT tested high quality IS2062 grade heavy duty material

- High Capacity Power pack system

- Heavy duty Electric motor for main drive

- Three type of modes of operation: manual, semi-auto, and Auto

- Foot switch Operated

- Movable work station

- Oil cup or Hand pump type lubrication system

- Sheet clamping system

- High quality punching die set

- Arrangement of easily punching pin disassembling so the holes distance is easily set without disassembling the punching pins.

- Special design Hydraulic cylinder

- Sufficient throat depth

- Fast and slow speed controlling system

- Double hydraulic pump operated hydraulic system

- Electric panel operated

- Direction control solenoid valve

- Pressure gauge for display operating pressure